Featuring John Brigham

We love shooting the Sony a7C II and a7CR because they are incredibly capable full frame cameras in a form factor that fits our travel style. The 200DLM/A Underwater Housing is designed to be just as compact as the camera for easy handling underwater.

We've set up the Deluxe 200DLM Underwater Housing for Sony a7C II and a7CR cameras exactly the way we would use it with Dual Tray with Dual Handles, Trigger Extensions, Vacuum System, and a set of spare O-Rings.

Follow along with the video or scroll down to read the full transcript.

Adding the Anti-Reflection Ring to the Lens

Okay, first things first, I'm going to turn my attention to the lens itself. You'll notice that if you look at this lens, you'll see white lettering on the face. Now, when you put this behind a dome port underwater, light is going to come through that dome port, it's going to hit these letters, and it's going to reflect back up into the dome port and then back into the lens so you may see this reflection in your images.

We're going to mitigate that reflection by adding an Anti-Reflection Ring # 0923.76 to our lens. Since I only have to do this one time, I'm going to take my time and make sure that it is well aligned.

Apply the far end of the anti-reflection ring to the lettering on the lens and carefully work it around the circumference, and making sure I'm going to cover all of those white letters. And that's as simple as that. Take your lens cap, put it back, set your lens aside.

We highly recommend using our Anti-Reflection Ring to prevent any unwanted lens lettering reflections appearing in your underwater images.

Installing the Camera & Lens in the Housing

Now we can turn our attention to the housing. The 200DLMA Underwater Housing for Sony a7C II, a7CR Deluxe Kit # 69124-DLX comes with a dual tray and handle, the trigger extensions that make both reaching the back button and the shutter very comfortable from that right handle, as well as the vacuum valve on the left side.

Set the housing down face, and we're going to release the locking mechanism on the lid hook, and we'll do that to the other side as well. Lift up, and then you can lift the locking mechanism up, and then up and over the hooks at the back, and now the back will simply just pull off straight. We'll take the back and set it to the side.

Turn our attention to the inside of the housing. What I like to do here is to make sure that my controls are going to be up and out of the way, so that when I install my camera, they're not going to interfere.

You'll notice that here in the middle, we have the camera mount. That features a 1/4-20 screw that's going to correspond to the bottom of our camera. This particular mount is going to work with both the a7C II or the a7CR. So, you don't have to worry about which one you choose for that.

We're going to set the housing to the side, grab our camera, take the screw, we're going to line it up on the back here, and take a flat-headed screwdriver, and you're going to make sure that that gets threaded down, and you're going to want to make sure this is snug down to the camera body. The anti-rotation wall on the mount will butt up against the LCD screen on the back of your camera. Keep this nice and snug. You don't want any movement between these two pieces because movement between these two pieces will translate to misalignment in the controls.

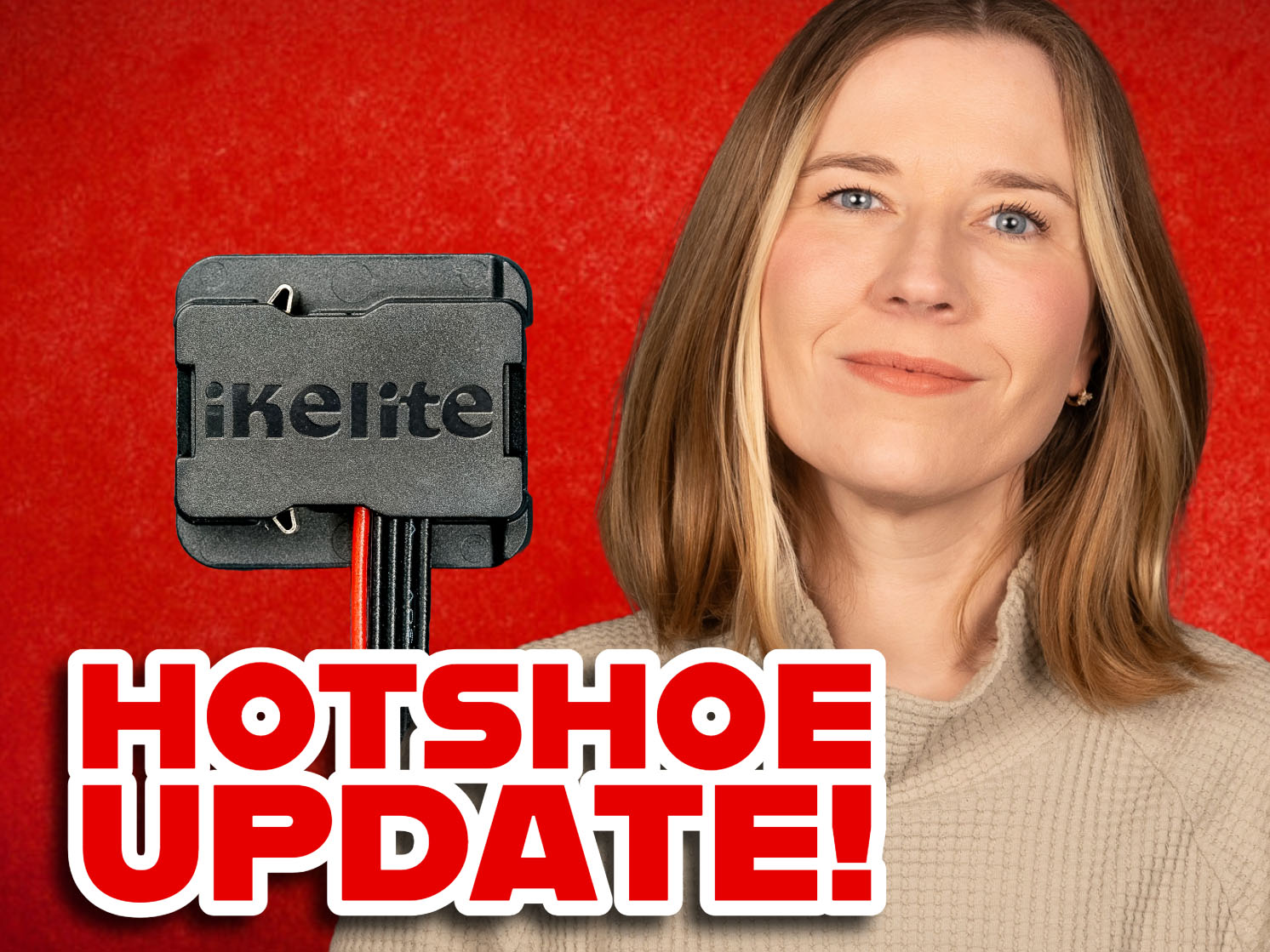

So, now we have our camera body, and if we go to the inside of our housing, you'll notice that just like the mount came out, it will slide back in. But before we do that, we're going to take the hotshoe and we're going to slide it into the camera, make sure it's fully forward and engaged. Now we just align the camera mount with the base, and slide the assembly into place.

The 1/4-20 screw seen here on the camera mount will screw into the designated tripod hole on the bottom of your camera. Ensure the mount is screwed in snuggly to prevent any mismatched alignment on your housing controls.

Take the opportunity to make sure all of your controls are aligned, and are going to operate when everything is sealed up.

Now, what we do is check our sealing surface. You want to make sure that's clean and free of debris. No lubricant is required for this particular seal. We just want to make sure that there is nothing that's going to compromise it like hair, dust, or debris. This is a compression seal, so the two faces will squeeze this. Because you don't have any friction to overcome, we don't need lubricant. While lubricant won't hurt this particular O-ring, it will have a tendency to attract extra debris. So, since we don't need it, I'm not going to put any lubricant on this O-ring, but I am going to make sure that it's clean.

Our corresponding sealing surface looks good. I'm going to align the back to the front of the housing, set it in place and I'm going to lift the lid snaps onto the hooks of each side, and then simultaneously I'm going to push down both the left and the right. You'll hear it snap into place on both sides, and as a confirmation, I like to pull up individually to make sure that they aren't going to open on their own and that the locking mechanism is engaged.

You'll notice that because the back is completely clear, not only can we see our camera, but we will be able to see that O-ring compress as we tighten those two lid hooks now.

Now, I'm just going to simply take the housing and set it down on its bottom.

The next thing we need to do is attach our lens and our port system. Now, in this particular case, you have a lot of lenses to choose from, which you'll need different ports depending on their different lengths and different driving mechanisms to zoom them. So take an opportunity, check out the Port Chart for this system, and make sure that you choose the right components for your lens.

In today's demonstration, I'm going to be using the Sony FE PZ 16-35mm f/4 G. Now, it's an affordable mid-range zoom lens that I like a lot. It's lightweight, and I also like that it is a PZ version of this lens, meaning it is a power zoom version of the lens. What that means is that I can zoom the lens through buttons on the back of the camera, as opposed to a drive mechanism around the circumference of the lens.

Take a look at our Sony PZ 16-35mm F4 Lens Zoom Gear Installation video and we can show you how to set that up on your camera. I already have mine set up that way, so we'll just jump straight into putting it onto the camera and then accommodating it with the port system.

Simply remove the body cap and the rear lens cap from your lens, and we're going to align the white dot with the white dot on the camera body. Bayonet it on like you normally would.

Installing the Lens Port

Now, let's turn our attention to the port system itself. In this particular scenario, I'm going to want the sharpest image I possibly can get, and in order to do that I will be using the DLM 8" Dome Port # 5516.82

I don't need a drive-in mechanism, again, because I'm utilizing the PZ version of this lens, but I will need an Extension # 5516.69 to accommodate the length, so the extension plus the dome port onto the housing will accommodate this lens. What I like to do is I like to put the extension onto the dome port, and then I like to put that assembly onto the housing.

You'll notice that on both the dome port and the extension, you have three thumb screws. These thumb screws act as a retaining mechanism. They don't create the seal, nor do they improve it. They keep the parts from being pulled apart. So, what we want to do is we want to make sure that the thumb screws are unthreaded so that they don't protrude onto the inside diameter of the part. In this particular case, I'm going to do that to both the extension and the dome port.

Now that I have my thumb screws out of the way, I can take some of the included Ikelite lubricant, and squeeze a small mount between your finger and thumb. What we want to do is lubricate both the O-ring of the extension by simply running our fingers over it. Also, take the time to visually inspect your O-ring, but also feel some things that would be compromising a seal aren't necessarily something you can see, but you can feel them. We're going to do the same thing to the O-ring on the port mount of the housing.

Then I also like to take an opportunity to check the sealing surfaces of those corresponding O-rings. On the extension, for example, that is right here where the O-ring is going to make contact. So, I can apply a little bit of additional lubricant and again feel for anything that's going to compromise this seal. I'll do the same thing on the 8-inch dome port. And we're good to go.

Notice the thumbscrews on the housing port mount, extension, and dome port are all properly aligned in this photo. One thumbscrew on the dome port will line up with the shade, this will orient to the top (or noon) of your housing.

Now, before we assemble this, I want you to make a quick note. There are three thumb screws. Only one of these three thumb screws is going to correspond to one of the shades of the port itself. That shade is going to be the top (or the noon position) of our housing. So, when we put everything together, we want that to be at the top.

Take your dome port, set it down on its face. Take your extension and we're going to line up the thumb screws and simply press together. In this case, we have to tighten the thumb screws of the dome port and that will engage the extension. And just like that went together, this assembly will now go onto the housing.

Because we've inspected and lubricated our O-ring, all we have to do is again make note of the thumb screw with the shade. That's going to be at the top. Press down until it's even all the way around and then simply tighten the thumb screws. You shouldn't feel resistance in these thumb screws. Again, they go behind a ledge and they keep the parts from being pulled apart. The seal occurred when we assembled the two components together. And when put a vacuum on the system all of these components will basically be sucked together.

That's as simple as that. Now we have a fully waterproof system with the Sony 16-35 PZ lens. And all we have to do at this point is put a vacuum on the system and we'll do a trim weight system on the bottom. And that's going to help counterbalance some of the extra buoyancy of the large dome port. And it'll be ready to get in the water.

Checking for Leaks with a Vacuum Pump

Next step, we have to put a vacuum on the housing. Now, what I recommend doing from personal experience is take an opportunity to take a few shots with the camera. Make sure I didn't leave my lens cap on, make sure that I have a card in my camera before I create a vacuum and have to go back and fix those things.

Now, to create a vacuum in this system, all we do is basically push the button on the side of the vacuum valve and it's going to release the cap. The cap is tethered so that you can't set it aside and lose it. You do want to make sure that this cap gets put back into the valve before you get in the water. That's very important.

The vacuum valve cap is tethered to your housing as an important reminder to never get in the water without this valve cap plugged in.

Next we're going to take the barb of the pump, and that's going to go where the cap came out of and then you're simply just going to pump the hand pump until you get to the desired level of vacuum. I usually recommend going to 10 or maybe 15. But the number that you choose isn't nearly as important as the fact that the vacuum isn't changing. The vacuum changing is going to indicate a leak. And of course, that's going to be a problem in the water.

What I'm looking for initially after creating a vacuum is the needle. If the needle is steadily dropping at that point, I have a major problem that I need to address and discover and fix. In this particular scenario, that needle is staying right where we left it.

What I could do is I could leave this set up like this and come back 15-20 minutes later and see if it's changed. I don't particularly like doing that because if this pump, this hose or barb is compromised, that will give me a false reading that I have a compromised system. So, what I do is I remove the barb from the valve by pushing the button, reinserting the plug, and letting this sit by itself. Now, this is the system I'm going to be diving with. That's the system I want to test.

Ideally, I've done this the night before, and this is all ready to go and set up. Right next to the door, so I can grab it on the way out. I've got my camera's power settings so that they fall asleep and I never actually have to activate the on-off switch of the camera, so this would be ready to go. That's set like this all night long.

Now, the next day, I can come in, reinsert my pump and check that the reading when right back to where it was and I'm good to go. I know that this held vacuum for that long. If you don't have the luxury of doing it overnight, give yourself 10, 15, 20, or 30 minutes that you can let this system set, and having set that it's held the vacuum for that amount of time. If it hasn't, or that number's changed, then you need to go in to investigate what happened. Maybe an o-ring or a hair or something like that. But other than that, that's ready to go.

For future reference, you will not be able to disassemble the system until you've released the vacuum on the system itself. To do so, you want to put your pump in. You'll notice there's a release button on the pump. If you have the older pump, it's a lever, and that will release the vacuum and let you disassemble the whole system.

If you don't have access to this pump, you can push a pencil or a pen, something that's not sharp, down into the valve, that will release the button, and therefore release the vacuum.

The rail on the trim weight allows you to move your attached weight up or down to control the pitch of your housing underwater.

Adding the Trim Weight System

Because I have this larger 8-inch dome port, and I'm not going to be using strobes in today's scenario, I'm actually going to put the trim weight on the bottom, and that will help me perfectly trim out this dome port when I'm in the water, front to back, and overall buoyancy. I'll show you how to put that on real quick. But, if you'd like to see a more detailed description watch our Trim Weight System for Perfect Housing Stability Underwater video.

Now, here's our Trim Weight System for DLM Housings # 47141. This is going to stick out below the dome port. It gets attached to the bottom tray. Now, you'll notice there is an extension, and that's going to help balance the system.

In today's demonstration, I have a particularly heavy weight, but that's the beauty of this system. This is weight that I do not have to travel with, nor will it take up room in my luggage because dive weights are easy to come by in dive locations. Probably around a 2-pound weight or something in that range would be a good suit for this.

All we have to do is take our extension, and we're going to line it up with one of the 1/4-20 holes on the bottom of this tray. What we're going to do is line it up with one of holes corresponding with the direction the port is offset. Then our threaded thumbscrew is going to go in through the rail and the extension. Loosen that knob a little bit and you can actually jog this weight forward and backwards because it slides on that rail. Tighten it down at the desired location, and that will control the pitch of your system. The weight will control the overall buoyancy, but you can control how much it leans forward or backwards by adjusting the weight on the rail.

Now, this is ready to get in the water, and we're all set. We have a vacuum, we have a trim weight system, and we're good to go. If you have any questions shoot us an email to ikelite@ikelite.com.

Products Shown

-

200DLMA Underwater Housing for Sony a7C II, a7CR Deluxe Kit # 69124-DLX

-

DLM 8" Dome Port # 5516.82

-

Extension # 5516.69

-

Anti-Reflection Ring # 0923.76

- Trim Weight System for DLM Housings # 47141

Additional Viewing

POWER ZOOM Your Sony PZ Lens Underwater [VIDEO]

Sony PZ 16-35mm F4 Lens // Zoom Gear Installation DLM/A Underwater Housing [VIDEO]

Using a Trim Weight System for Balance and Stability Underwater

Sony a7C II & a7CR // DL vs DLM Ikelite Underwater Housing [VIDEO]

Sony a7C II Underwater in Fiji // Ikelite 200DLM/A Underwater Housing [VIDEO]

Sony a7C II Underwater in Grand Cayman [VIDEO]

Laowa 10mm FIRST RESULTS Underwater with the Sony a7CR [VIDEO]

John Brigham is the Vice President & head of product development at Ikelite. He was born with a flair for design and an entrepreneurial spirit as son of Ikelite founder Ike Brigham. He worked his way up in the business and is a natural fit in the R&D side of things. John dives the equipment as much as possible to test product and put himself in the "fins" of the user. You may also find him on the other end of an email or phone call when you reach out for product advice and support. When he's not underwater he's flying drones, setting off rockets, training his German Shepherd "T2", and spending time with his family.

John Brigham is the Vice President & head of product development at Ikelite. He was born with a flair for design and an entrepreneurial spirit as son of Ikelite founder Ike Brigham. He worked his way up in the business and is a natural fit in the R&D side of things. John dives the equipment as much as possible to test product and put himself in the "fins" of the user. You may also find him on the other end of an email or phone call when you reach out for product advice and support. When he's not underwater he's flying drones, setting off rockets, training his German Shepherd "T2", and spending time with his family.

![Sony a7C II & a7CR Setting It Up // 200DLM/A Underwater Housing [VIDEO]](http://www.ikelite.com/cdn/shop/articles/Sony_a7C_II_a7CR_200DLM_Assembly_520x500_520x500_520x500_520x500_520x500_520x500_520x500_520x500_520x500_520x500_520x500_520x500_520x500_520x500_5_b62139e1-c960-4943-a936-7830dff5c8a0.jpg?v=1738781281&width=1500)